Specification

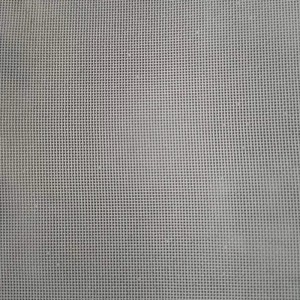

The coating is available in 100% Sterling silver or antique silver, which can be customized according to the customer's application environment.

Advantage

Silver coated is much cheaper than gold coated, and has high electrical conductivity, light reflectivity, and chemical stability to organic acids and alkalis, so it is much more widely used than gold.

Application

The silver coated layer is easy to polish, has strong reflective ability and good thermal conductivity, electrical conductivity and welding performance. Silver coating was first used in decoration. In the electronics industry, communication configuration and instrumentation manufacturing, silver coating is generally used to reduce the resistance of metal parts and improve the welding ability of metals. Metal reflectors in searchlights and other reflectors also need to be silver coated. Because silver atoms are easy to diffuse and slip along the surface of the material, it is easy to breed "silver whiskers" in a humid atmosphere and cause short circuits, so silver coating is not suitable for use in printed circuit boards.

What does silver plating do? The biggest function of silver plating is to use the coating to prevent corrosion, increase conductivity, reflectivity and beauty. Widely used in manufacturing industries such as electrical appliances, instruments, meters and lighting appliances.

Silver plating is easy to polish, has strong reflective ability and good thermal conductivity, electrical conductivity, and welding performance. Silver plating was first used for decoration. In the electronic industry, communication equipment and instrumentation manufacturing industry, silver plating is widely used to reduce the contact resistance on the surface of metal parts and improve the welding ability of metal.