Specification

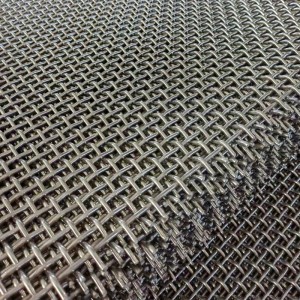

Material: 304、304L、316/316L、317L、904L、Duplex steel etc.

|

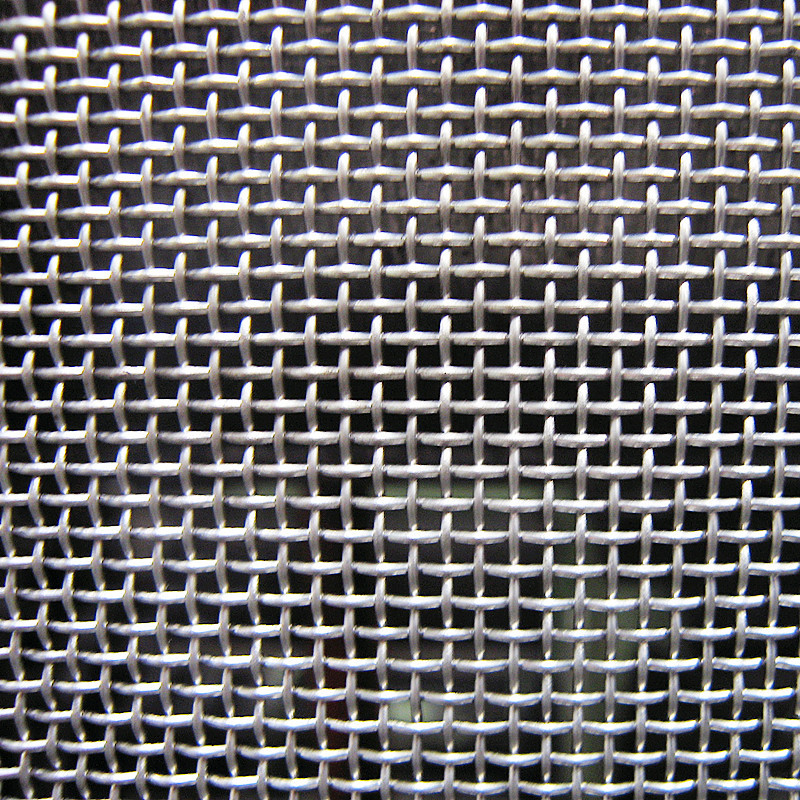

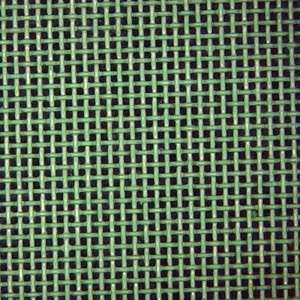

Plain weave Specifications |

|||||||

|

Product code |

Warp mesh |

Weft mesh |

Wire diameter |

Aperature |

Open area |

||

|

inch |

mm |

inch |

mm |

(%) |

|||

| SPW-2/3.0 |

2 |

2 |

0.1180 |

3.0 |

0.382 |

9.70 |

58.4 |

| SPW-4/1.6 |

4 |

4 |

0.0630 |

1.6 |

0.2 |

4.75 |

56.0 |

| SPW-4/1.2 |

4 |

4 |

0.0470 |

1.2 |

0.203 |

5.16 |

65.9 |

| SPW-6/1.2 |

6 |

6 |

0.0470 |

1.2 |

0.120 |

3.04 |

51.6 |

| SPW-8/0.7 |

8 |

8 |

0.0270 |

0.7 |

0.098 |

2.49 |

61.5 |

| SPW-10/0.8 |

10 |

10 |

0.0315 |

0.800 |

0.069 |

1.74 |

46.9 |

| SPW-10/0.5 |

10 |

10 |

0.0200 |

0.508 |

0.080 |

2.03 |

64.0 |

| SPW-12/0.6 |

12 |

12 |

0.0235 |

0.60 |

0.060 |

1.52 |

51.6 |

| SPW-12/0.5 |

12 |

12 |

0.0200 |

0.508 |

0.063 |

1.61 |

57.8 |

| SPW-14/0.6 |

14 |

14 |

0.0235 |

0.597 |

0.048 |

1.22 |

45.0 |

| SPW-14/0.5 |

14 |

14 |

0.0200 |

0.508 |

0.051 |

1.31 |

51.8 |

| SPW-16/0.6 |

16 |

16 |

0.0235 |

0.597 |

0.039 |

0.99 |

38.9 |

| SPW-16/0.45 |

16 |

16 |

0.0175 |

0.445 |

0.045 |

1.14 |

51.8 |

| SPW-18/0.4 |

18 |

18 |

0.0160 |

0.406 |

0.040 |

1.00 |

50.7 |

| SPW-20/0.5 |

20 |

20 |

0.0200 |

0.508 |

0.030 |

0.76 |

36.0 |

| SPW-20/0.4 |

20 |

20 |

0.0160 |

0.406 |

0.034 |

0.86 |

46.2 |

| SPW-24/0.35 |

24 |

24 |

0.0140 |

0.356 |

0.028 |

0.70 |

44.1 |

| SPW-30/0.3 |

30 |

30 |

0.0120 |

0.305 |

0.021 |

0.54 |

41.0 |

| SPW-30/0.25 |

30 |

30 |

0.0100 |

0.254 |

0.023 |

0.59 |

49.0 |

| SPW-35/0.25 |

35 |

35 |

0.0100 |

0.254 |

0.019 |

0.47 |

42.3 |

| SPW-40/0.25 |

40 |

40 |

0.0100 |

0.254 |

0.015 |

0.38 |

36.0 |

| SPW-50/0.2 |

50 |

50 |

0.0080 |

0.203 |

0.012 |

0.30 |

36.0 |

| SPW-50/0.15 |

50 |

50 |

0.0060 |

0.152 |

0.014 |

0.36 |

49.0 |

| SPW-60/0.15 |

60 |

60 |

0.0060 |

0.152 |

0.011 |

0.27 |

41.0 |

| SPW-60/0.13 |

60 |

60 |

0.0050 |

0.127 |

0.012 |

0.30 |

49.0 |

| SPW-80/0.13 |

80 |

80 |

0.0050 |

0.127 |

0.008 |

0.19 |

36.0 |

| SPW-80/0.1 |

80 |

80 |

0.0040 |

0.102 |

0.009 |

0.22 |

46.2 |

| SPW-90/0.11 |

90 |

90 |

0.0045 |

0.114 |

0.007 |

0.17 |

35.4 |

| SPW-90/0.1 |

90 |

90 |

0.0040 |

0.102 |

0.007 |

0.18 |

41.0 |

| SPW-100/0.11 |

100 |

100 |

0.0045 |

0.114 |

0.006 |

0.14 |

30.3 |

| SPW-100/0.1 |

100 |

100 |

0.0040 |

0.102 |

0.006 |

0.15 |

36.0 |

| SPW-120/0.09 |

120 |

120 |

0.0035 |

0.089 |

0.005 |

0.12 |

33.6 |

| SPW-120/0.08 |

120 |

120 |

0.0030 |

0.076 |

0.005 |

0.14 |

41.0 |

| SPW-150/0.06 |

150 |

150 |

0.0025 |

0.064 |

0.004 |

0.11 |

39.1 |

| SPW-180/0.06 |

180 |

180 |

0.0023 |

0.058 |

0.003 |

0.08 |

34.3 |

| SPW-200/0.05 |

200 |

200 |

0.0020 |

0.051 |

0.003 |

0.08 |

36.0 |

| SPW-250/0.04 |

250 |

250 |

0.0016 |

0.041 |

0.002 |

0.06 |

36.0 |

| SPW-270/0.035 |

270 |

270 |

0.0014 |

0.035 |

0.002 |

0.06 |

39.4 |

| SPW-300/0.03 |

300 |

300 |

0.0012 |

0.030 |

0.002 |

0.05 |

41.7 |

| SPW-325/0.028 |

325 |

325 |

0.0011 |

0.028 |

0.002 |

0.05 |

41.2 |

| SPW-400/0.025 |

400 |

400 |

0.0010 |

0.025 |

0.002 |

0.04 |

36.0 |

Note: Special specifications can also be available according to customers’ requirement.

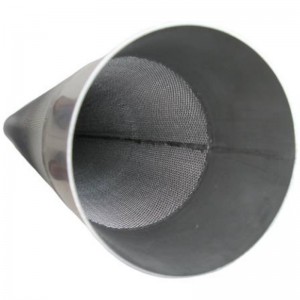

Applications: Mainly used in particle screening and filtration, including petrochemical filtration, food and medicine filtration, building materials screening etc.

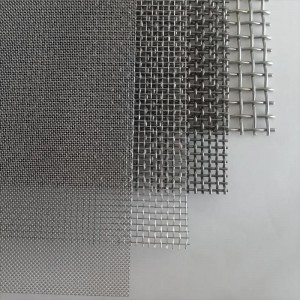

The standard width is between 1.3m and 3m.Customer-specific productions are available up to a width of 5.0m.

The standard length is 30.5m(100 feet). Other sizes can be customized.

Metal wire mesh belongs to the category of stainless steel wire mesh, which can be cut into pictures of various specifications. Rectangular pieces can also accept incoming materials for processing. Our company has long been committed to high-quality stainless steel woven mesh products, and is equipped with various inspection equipment. Can be customized according to customer requirements.

Product production process: the radial and weft wire diameters are the same, each diameter wire crosses every two (or more) weft wires, and each weft wire crosses every two (or more) weft wires It is made of silk crossed up and down.

Daily maintenance of wire mesh: washing machine is the basic work of equipment maintenance, which must be institutionalized and standardized. For the regular maintenance of equipment, work quotas and material consumption quotas should be formulated, and assessments should be carried out according to the quotas. Regular maintenance of equipment should be included in the assessment content of the workshop contract responsibility system.